Project Title: Development of a High Performance Flowing Electrolyte-Direct Methanol Fuel Cell Stack Through Modeling and Experimental Studies

Source of Funding: Horizon2020-MSCA-IF-2014

Project Dates: 09/2015-09/2017

Partner Organization: Forschungszentrum Jülich GmbH (Dr. Martin Müller)

Summary

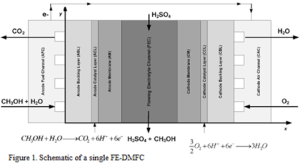

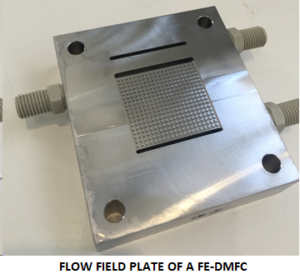

Flowing electrolyte-direct methanol fuel cell (FE-DMFC) is a novel energy technology in which the performance of the conventional DMFC is increased by eliminating the methanol crossover problem. There are some studies found in the literature to predict the performance of this fuel cell using one and two-dimensional single phase models. The validation of these models was done using the experimental test results for the membrane electrode assemblies (MEA) built with conventional materials. In this project, the main objective is to develop a high performance FE-DMFC stack through modeling and experimental studies. For this purpose, a three-dimensional and two-phase multiphysics model, which includes all the transport phenomena in all the layers, will be developed to predict the performance of the FE-DMFC stack accurately. To validate this model, a FE-DMFC based on alternative materials will be manufactured in-house in cooperation with the partner organization in Germany (Forschungszentrum Jülich GmbH). After validating this model, the effect of significant design and operating parameters on the output parameters will be investigated; thus the parameters that increase the performance of this fuel cell mostly will be determined. It is expected that the results of this project will make a significant progress toward commercialization of the FE-DMFC, which in turn contributes to the economy and social prosperity of European society.

Research Highlights

- The FE-DMFC can decrease the methanol crossover significantly.

- High faradaic efficiencies up to 98% are possible with the FE-DMFC at different cell current densities.

- Methanol crossover can be reduced by a factor of 10, but the reduction is more limited in FE-DMFCs having thin membranes and high methanol concentrations.

- Nafion® 115 based FE-DMFC has the best performance (0.38 V at 0.1 A/cm2) when it operates with 1 M methanol concentration and 5 ml/min sulfuric acid flow rate

- The maximum power density of the FE-DMFC was achieved as 0.0561 W/cm2 (for N212 based FE-DMFC operating with 3 M methanol concentration at 0.3 A/cm2)

- Flowing electrolyte thickness, flowing electrolyte flow rate and methanol concentration are the most important parameters affecting the performance of the FE-DMFC

- In a FE-DMFC stack, the cells furthest from the outlet manifold in a U-shaped configuration have the least amount of flow. This lead the anode methanol concentration distribution to have a low uniformity in these cells.

- The porous flowing electrolyte channel had a significantly higher pressure drop than the anode flow field and cathode flow field. However, the porous FEC material allowed for a uniform pressure, and thus flow distribution between cells.

PRESENTATIONS

Seminars

- Colpan, C.O., Ouellette, D. Progress in the Development of Flowing Electrolyte – Direct Methanol Fuel Cells. Forschungszentrum Jülich, IEK-3, Jülich, Germany. July 5, 2016.

- Colpan, C.O., Ouellette, D., Glüsen, A., Müller, M. Reduction of Methanol Crossover in a Flowing Electrolyte – Direct Methanol Fuel Cell. Forschungszentrum Jülich, IEK-3, Jülich, Germany. September 14, 2016.

Oral Presentations in Conferences

- Atacan, F., Ouellette, D., Colpan, C.O. Multiphase Non-Isothermal Modeling of a Flowing Electrolyte – Direct Methanol Fuel Cell. 8th International Exergy, Energy and Environment Symposium (IEEES-8), Antalya, Turkey, May 1-4, 2016.

- Gencalp, U., Ouellette, D., Colpan, C.O. Effect of Anode Flow Field Design on Flowing Electrolyte-Direct Methanol Fuel cell. World Hydrogen Energy Conference, Zaragoza/Spain. June 13-16, 2016.

- Ouellette, D., Colpan, C.O. Numerical Studies of a 3D DMFC Short-Stack. 9th International Exergy, Energy and Environment Symposium (IEEES-9), May 14-17, 2017, Split, Croatia.

- Atacan, O.F., Ouellette, D., Colpan, C.O. Three Dimensional and Two Phase Modeling of a Flowing Electrolyte – Direct Methanol Fuel Cell. 9th International Exergy, Energy and Environment Symposium (IEEES-9), May 14-17, 2017, Split, Croatia.

Poster Presentation in Conference

- Colpan, C.O. Advances in the Direct Methanol Fuel Cell Research in Dokuz Eylul University. 647. WE-Heraeus-Seminar on Next Generation PEM Fuel Cells: Strategic Partnerships for Tackling Multiscale Challenges, July 2-5, 2017, Bad Honnef, Germany

PUBLICATIONS

- Atacan, F., Ouellette, D., Colpan, C.O. Multiphase Non-Isothermal Modeling of a Flowing Electrolyte – Direct Methanol Fuel Cell. 8th International Exergy, Energy and Environment Symposium (IEEES-8), Antalya, Turkey, May 1-4, 2016. [OpenAIRE]

- Colpan, C.O., Ouellette, D., Glüsen, A., Müller, M., Stolten, D. 2017. Reduction of methanol crossover in a flowing electrolyte-direct methanol fuel cell. International Journal of Hydrogen Energy. 42(33). pp. 21530-21545. [OpenAIRE]

- Ozden, A., Ercelik, M., Ozdemir, Y., Devrim, Y., Colpan, C.O., 2017. Enhancement of direct methanol fuel cell performance through the inclusion of Zirconium Phosphate. International Journal of Hydrogen Energy. 42(33). pp. 21501-21517. [OpenAIRE]

- Ouellette, D., Colpan, C.O. Numerical Studies of a 3D DMFC Short-Stack. 9th International Exergy, Energy and Environment Symposium (IEEES-9), May 14-17, 2017, Split, Croatia. [OpenAIRE]

- Atacan, O.F., Ouellette, D., Colpan, C.O. Three Dimensional and Two Phase Modeling of a Flowing Electrolyte – Direct Methanol Fuel Cell. 9th International Exergy, Energy and Environment Symposium (IEEES-9), May 14-17, 2017, Split, Croatia. [OpenAIRE]

- Colpan, C.O., Ouellette, D. Three Dimensional Modeling of a FE-DMFC Short-Stack. International Journal of Hydrogen Energy. (Submitted) [OpenAIRE]